Cutting-edge scanning technology developed in Rotherham is playing a crucial role in the restoration of a prized 18th century statue at Wentworth Woodhouse. The white-marble statue, which stands at the foot of the Grade I listed mansion’s grand staircase, is in need of some TLC.

Over 270 years old, it depicts Ancient Roman General and politician Germanicus, who was father to the emperor Caligula. It was created in the 1750s for the Second Marquess of Rockingham by Italian Filippo Della Valle, whose work adorns Rome’s Trevi Fountain. It journeyed to Rotherham in the 1760s and was displayed in the house for 140 years, before being moved to the garden’s Camellia House in 1902.

But by the late 1900s, the Camellia House roof failed and, left open to the elements, the statue became heavily water-stained. It was moved back into the house in the 1980s, however the damage was done.

The Preservation Trust, which took ownership of Wentworth Woodhouse in 2017, wants to restore and preserve the Germanicus – and its first step was to turn to 21st century tech developed by two organisations at Rotherham’s Advanced Manufacturing Park.

The Trust collaborated with the University of Sheffield Advanced Manufacturing Research Centre (AMRC), a member of the High Value Manufacturing Catapult network, and PES Scanning, part of Performance Engineered Solutions (PES) Ltd.

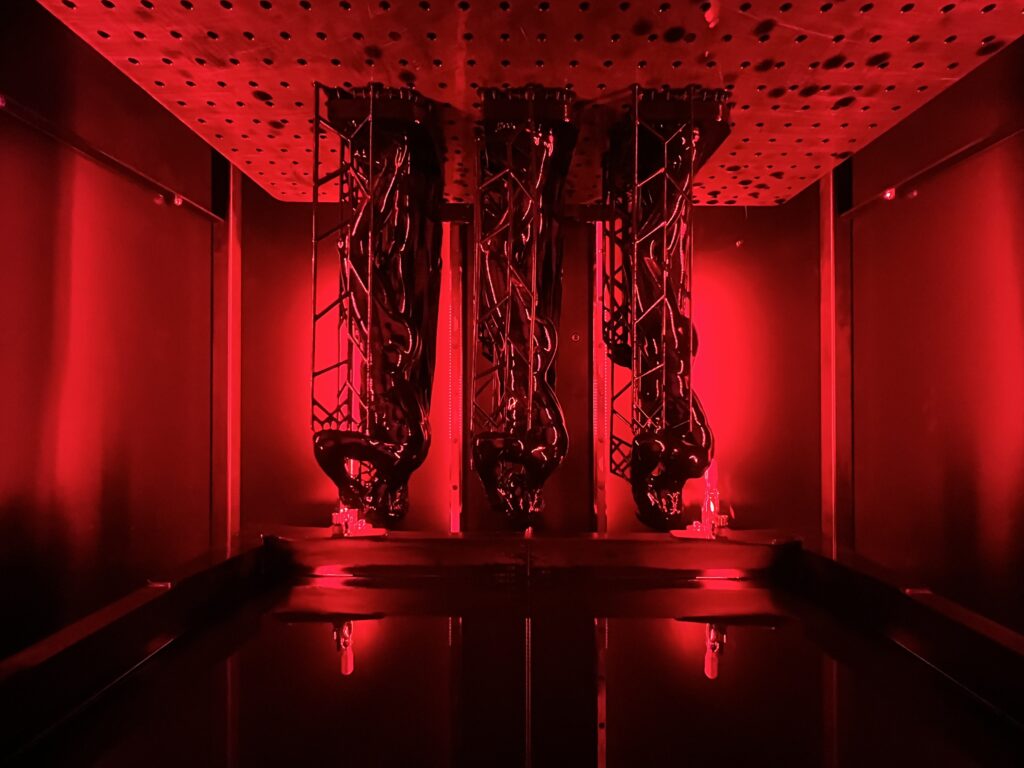

Using reverse-engineering technology, PES created a highly-accurate 3D scan of the statue. This ‘digital blueprint’ was then used by the AMRC’s design experts to 3D-print three miniature replicas of the Germanicus.

The manufacture took just 31 hours using the AMRC’s Photocentric LC Magna 3D Printer, which is capable of creating large, high-detail, low-cost parts. The miniatures each weigh 348 grams and are 29cm in height – a fraction of the real Germanicus, which is 180cm tall.

Wentworth Woodhouse Preservation Trust can now use the 3D scan to monitor any further deterioration to the Germanicus, and could have an exact copy created if the statue was ever seriously damaged. It also means that miniature statues of Ancient Rome’s esteemed General could one day line the shelves in the Trust’s gift shop to boost fundraising.

“Ideas so far include making small, museum-quality replicas, or having fun and turning out Germanicus chocolate statues,” said Steve Ash, WWPT’s Digital Projects Manager.

“The use of digital technologies at Wentworth Woodhouse is in its early stages, but there’s no doubt it will have an important role to play in both conservation and entrepreneurialism.

“The AMRC and PES Scanning have shown us the possibilities that lie ahead. We are looking forward to working together again.”

AMRC Training Centre apprentice Harry Howson, who works for PES Scanning, helped to scan and digitise the statue using a hand-held 3D laser scanner, which captured every detail of the statue to an accuracy of 0.020mm and a resolution capability of 0.01mm, taking up to 1.6 million measurements per second.

Specialist software meshed the measurement points into surfaces, or ‘point clouds’ and the AMRC’s design experts used the scans to 3D-print the three miniature replicas.

Each weighing 348 grams and 29cm high – around a sixth of the size of the real Germanicus, which is 180cm tall – they were manufactured in just 31 hours using the AMRC’s Photocentric LC Magna 3D Printer.

Nathan Bailey, metrology applications engineer at PES Scanning, said: “We provide metrology and 3D scanning services from aerospace to construction and are constantly expanding the areas we work in, so this project with the AMRC and Wentworth Woodhouse was a fantastic opportunity for us. Our apprentice, Harry, was able to get his teeth into a project very different to the engineering situations we usually see.

“Data capturing technology has an important role to play in addressing the heritage challenges of today. It allows us to visualise how items or buildings were when they were originally created, which helps greatly if they need to be restored to their former glory.”

Phil Yates, SME senior engineer at the AMRC integrated manufacturing group, said: “We were very proud to implement our design and prototyping expertise for Wentworth Woodhouse. The project also showed showed how nurturing and guiding young manufacturing talent is at the heart of the AMRC’s mission.

“Technology is developing rapidly and has the potential to not only make a better tomorrow, but also to conserve and restore the past. The Germanicus project was an integral step towards this. We hope to explore many such avenues, and continue our collaboration with Wentworth Woodhouse.”